Top Features to Look for When Purchasing Industrial Scales for Your Facility

Top Features to Look for When Purchasing Industrial Scales for Your Facility

Blog Article

Why to Pick Industrial Scales for Accurate Weight Measurement in Various Industries

In an era where accuracy is extremely important, the selection of industrial ranges for accurate weight measurement plays a vital duty throughout varied industries. These ranges not just enhance functional effectiveness but also ensure conformity with governing requirements, impacting every little thing from manufacturing to shipping. Their durable layout and progressed modern technology deal with numerous applications, reinforcing the demand for precise weight management. Comprehending the nuances of these ranges is crucial for any type of company intending to enhance processes and alleviate expensive errors. The question stays: what certain aspects should one think about when picking the right scale for their unique functional needs?

Relevance of Accurate Weight Dimension

In the world of commercial operations, the relevance of precise weight measurement can not be overemphasized. Exact weight dimension is fundamental across numerous sectors, influencing both functional effectiveness and product quality - Industrial Scales. It acts as a vital element in inventory administration, ensuring that materials are adequately accounted for, therefore lessening waste and lowering costs

In manufacturing, accurate weight measurement directly affects manufacturing processes. Anomalies in weight can result in substandard items or too much resource allotment, impacting total profitability. Additionally, in markets such as drugs and food production, adherence to strict weight specs is vital for regulative conformity and customer safety.

Additionally, precise weight measurements help with effective logistics and supply chain monitoring. Appropriately weighed shipments ensure that transportation prices are maximized which stock levels are maintained accurately, thereby preventing stock shortages or overstock circumstances.

Types of Industrial Scales

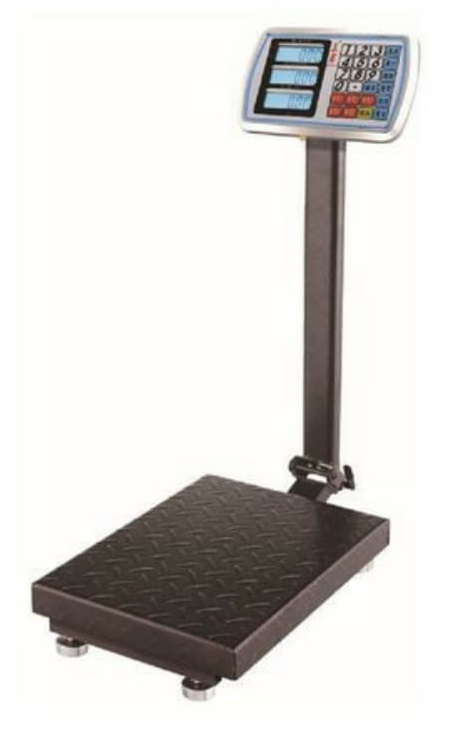

A wide range of commercial ranges are offered, each developed to meet particular measurement requires throughout varied markets. Typical types include flooring ranges, which are suitable and durable for evaluating large items or pallets in warehouses and circulation. Bench scales are smaller sized and perfect for lighter materials, commonly used in retail setups or manufacturing for exact section control.

Another category is portable ranges, which provide the versatility to be moved easily around work websites, making them optimal for area operations or momentary setups. Precision scales, on the various other hand, are made for high precision and are frequently used in laboratories and top quality control settings.

Lots cells are critical parts in various industrial ranges, transforming push into an electric signal for precise analyses. Furthermore, vehicle scales provide the means to consider heavy automobiles and their lots, ensuring conformity with laws and optimizing logistics.

Lastly, checkweighers immediately compare the weight of products against predetermined restrictions, improving quality control in assembly line (Industrial Scales). Each type of industrial range offers a distinct feature, satisfying the details needs of markets such as production, logistics, food handling, and drugs

Benefits of Utilizing Industrial Scales

Continually utilizing commercial scales provides considerable advantages throughout different sectors. One of the her explanation main advantages is improved accuracy in weight measurement, which is essential for maintaining high quality requirements and regulative conformity. Precise dimensions avoid pricey errors in production, supply, and delivery administration, ultimately bring about increased functional effectiveness.

In addition, industrial scales are developed for toughness and effectiveness, permitting them to endure harsh environments normally located in production and warehousing. This strength guarantees a long lifespan, reducing the requirement for constant replacements and maintenance expenses.

Additionally, utilizing commercial ranges improves security and decreases waste. By guaranteeing that items are weighed properly, business can avoid straining vehicles, which can bring about crashes and penalties.

Applications Throughout Numerous Industries

Industrial ranges play a pivotal role in many markets, consisting of production, logistics, food processing, and drugs. In production, these ranges are important for making sure that basic materials are determined properly, thus maintaining item high quality and consistency (Industrial Scales). Precision in weight dimension straight impacts production efficiency and Website cost management

In logistics, commercial ranges assist in the exact considering of deliveries, which is vital for adhering to shipping laws and enhancing freight costs. Exact weight data assists streamline procedures and boosts supply chain management.

The food handling market relies greatly on industrial ranges for compliance with wellness and safety and security policies. They are used to evaluate active ingredients exactly, making sure that formulations meet both high quality criteria and lawful requirements. This is important not just for consumer safety and security but also for keeping brand stability.

Pharmaceutical firms utilize commercial scales to make certain exact does in medication production, where also the tiniest discrepancy can have substantial effects. Compliance with rigid regulatory standards makes specific weight dimension vital in this field.

When Choosing Scales,## Elements to Think About.

Picking the right range for certain applications needs careful consideration of several variables. The capacity of the range is important; it must fit the maximum weight of the items being gauged without exceeding its limits. In addition, the readability, or smallest increment the range can precisely present, is important for accuracy, particularly in industries where weight discrepancies can result in significant economic losses or safety problems.

Environmental conditions likewise play a considerable duty in scale choice. Scales used in corrosive or damp settings might call for customized products to guarantee durability. Portability might be necessary in particular applications, necessitating battery-operated and light-weight models.

Conclusion

In conclusion, the option of industrial scales is crucial for ensuring exact weight dimension throughout diverse markets. Hence, investing in high-quality industrial ranges is essential for companies aiming to take full advantage of and keep high requirements profitability.

Report this page